Key Differences Between SOLIDWORKS and Rhino

With several 3D design software now on the market, it’s important to understand their differences to determine which solution is best for your design needs. We broke down the key differences between SOLIDWORKS and Rhino so you can see where each software aligns with your workflow.

SOLIDWORKS and Rhino At Their Core

SOLIDWORKS is a parametric solid modeling software, which means you have everything that’s captured with fully defined and constrained features. With a complete feature history, you can go back at any point and change a parameter of one feature, which will cascade down to any subsequent changes in the design history.

Rhino uses a direct modeling approach which generates geometry quickly and easily without worrying about constraints. However, Rhino falls short when it comes to historical changes. To make changes to a project you previously worked on, you would have to directly modify what you have in front of you as if you are modeling with virtual clay.

Industries that use SOLIDWORKS and Rhino

Another factor where SOLIDWORKS and Rhino differ is the industries they serve. Rhino is commonly used in an architecture or industrial design approach where users don’t necessarily have specific parameters in terms of dimensions to meet. This software is also used for fast prototype ideation, jewelry, and marine architecture.

SOLIDWORKS, on the other hand, is more often used for fully engineered products with fully defined components that can be put into assemblies to create 2D drawings. Rhino has the ability to do some 2D generation off of their 3D models, but in SOLIDWORKS, you’re able to create fully annotated prints with all of the dimensions laid out so that a print off of a 3D model can go straight into production. With each iteration, many of the elements found in Rhino that designers were used to accessing can also be achieved in SOLIDWORKS. Interested in finding out how? Connect with us, we’d be happy to explore these options with you.

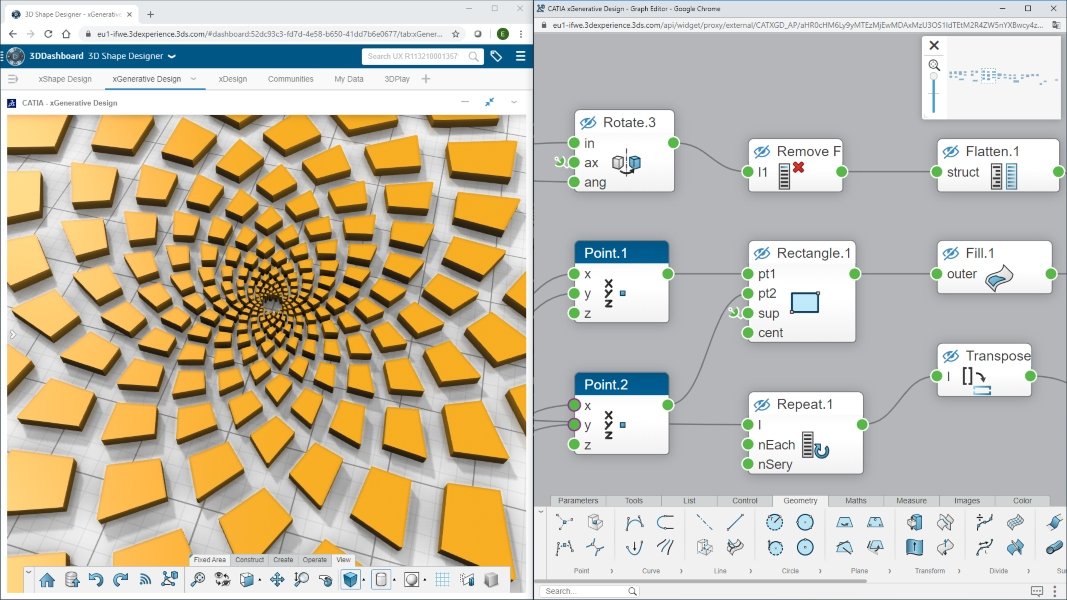

Node-Based Programming

Rhino provides a node-based programming approach to generative design, which is handled by a tool called Grasshopper. With Grasshopper, Rhino users can do limited parametric modeling. This allows designers to take advantage of the free-form nature of Rhino but add more control to their designs and more easily make any changes downstream.

At its core, SOLIDWORKS uses parametric modeling, but it does not have node-based generative design built into it. However, the xGenerative Design App, which can be accessed through the 3D Pattern Shape Creator role on the 3DEXPERIENCE platform, can be paired with SOLIDWORKS to add node-based generative design capabilities to your workflow.

Modeling Technology in each Software

Rhino stands out with its subdivision modeling technology which basically takes virtual modeling clay and allows users to push and pull the clay into the shape they’re looking for. The finished result has nice surface continuity with a clean, complex organic surface geometry.

SOLIDWORKS does not have these capabilities internally, but when paired with xShape, which can be accessed on the 3DEXPERIENCE platform via the 3DSculptor role, users can add this to their toolset as well. The 3DEXPERIENCE SOLIDWORKS package bundles SOLIDWORKS and xShape together, which gives users traditional parametric design and subdivision modeling technology together. The xGenerative Design app can be added to this bundle to provide node-based generative design capabilities as well.

Where SOLIDWORKS Surpasses Rhino Capabilities

SOLIDWORKS goes beyond Rhino's capabilities in terms of its family of products. SOLIDWORKS products expand into simulation, like FEA or CFD, CAM solutions like CNC milling, rendering capabilities, and beyond. While Rhino does have photorealistic renderings as well, Rhino is more often used as a freeform quick ideation tool, whereas SOLIDWORKS takes products to the finish line with a fully defined constrained model that can be used in manufacturing.

Can Files be Transferred from Rhino to SOLIDWORKS?

When it comes to transferring files or working with different file types, SOLIDWORKS is more compatible than Rhino. For example, you can take a 3DM file from Rhino and directly import the file into SOLIDWORKS, which becomes a solid or surface body, ready to use in your designs. Generic STEP, IGES, STL, and OBJ files can be imported as well, along with many others. If you transition from Rhino to SOLIDWORKS, your files will be easy to transfer and begin working on.

If you’re running into limitations in your workflow or have additional questions about how Rhino compares to SOLIDWORKS, reach out to our team. We’d be happy to help you navigate the two options and help you find a bundle fit for your projects.

Matt is a Customer Success Manager at SWYFT Solutions and started using SOLIDWORKS while earning his Bachelor’s in Mechanical Engineering at Grand Valley State University and has been hooked ever since! He now specializes in 3DEXPERIENCE Works solutions, including 3DEXPERIENCE SOLIDWORKS. Outside of work, Matt loves to travel, hike, and discover new music.

Connect with Matt on LinkedIn